About this tech support page

This tech support page is based on our 30 plus years of experience doing performance work and custom installs. Please try to understand that no one project is the same. It is virtually impossible for us to make a "one manifold fits all", So Please let our experience help you with your project. More than likely if you think you have a problem, we already have an answer for you, if not we will learn! So please take the time to contact us for assistance, before you assume it is a problem. We may be able to save you time, grief and money! Please remember we are a working shop and are not always able to get to the phone, for this reason email is the best contact and typically will generate a quicker response to your technical needs. If you do call and we do not answer please be sure to leave a message and we will call you back asap.

It is important to know that you will need comprehensive mechanical abilities, knowledge and above average tools to complete the install of this system. More than likely there will be modifications required to fuel lines and such. The FIRST Tpi is designed to be used on all types of projects, so there really is just no way we can make a totally drop on version out of the box in mass production. Each intake is typically built to suit your individual project . The more information you supply, the better we can help you with your project. Again, we are here to help the best we can, so feel free to contact us before and during your project install. The FIRST tpi does NOT have EGR provisions.

Older FIRST tpi intakes

Many people are finding older air sensor FIRST Tpi intakes for sale on the internet. These were from the original company before we purchased the FIRST in 2000. All though they may seem like a good deal, we have found many of them are blems and were machined incorrectly. We have seen fitment issues with the majority of these that will cause extreme vacuum leaks. Many do not have the vac. ports installed, which is a red flag. If you do find one of these for sale, you can send us pictures and we will be more than happy to assist you with inspection before you purchase it at no charge. We would rather you be aware than be upset after the purchase. We can pretty much repair any of these and make them usable again, just beware of the cost associated with this when discussing a fair purchase price. The older ones will have "air sensors" on the underside of the base plate.

Common mistakes

MOST COMMON MISTAKE IS NOT CONTACTING US FOR HELP!

MOST COMMON MISTAKE IS NOT CONTACTING US FOR HELP!

MOST COMMON MISTAKE IS NOT CONTACTING US FOR HELP!

The most important thing to remember is to contact us BEFORE you assume something is wrong and attempt to modify something that probably does not need modification.

MAP sensor

MOST COMMON MISTAKE IS NOT CONTACTING US FOR HELP!

MOST COMMON MISTAKE IS NOT CONTACTING US FOR HELP!

We have found through years of tech support that many people do not realize the MAP sensor needs to be connected to a vacuum port. Please be sure that this sensor is connected to a vacuum port. If this sensor is not connected to a manifold vac. port the ecm will think the engine is under a load all the time and you will have an extreme rich running situation. We recommend the MAP bracket for the FIRST tpi and that you connect right to the 1/4 vac. port next to the bracket.

Runner install

MOST COMMON MISTAKE IS NOT CONTACTING US FOR HELP!

Adapting a OEM twin blade TB

Silicone on runner gaskets. Many people are using silicone on the runner gaskets when they are installed, we do not recommend this. The only silicone needed when you install the runners, would be on the lower middle passenger side runner bolt which does protrude into a water passage.

Adapting a OEM twin blade TB

Adapting a OEM twin blade TB

Adapting a OEM twin blade TB

Many people would like to try and adapt the OEM twin blade throttle body to the FIRST plenum. We do not recommend this. We have made such an adapter a few times and it creates a small opening approximately 2" X 3.250 at the entrance of the plenum. This is very restricted. The FIRST plenum is square and the OEM is narrow and wide, so to create a good transition to that small opening the adapter needs to be extremely thick, which causes other issues under the hood sometimes.

Reprogram the prom

Adapting a OEM twin blade TB

Fuel lines modifications

If you are installing the FIRST Tpi on an existing OBD1 car and you change injector size, cam or heads etc. You will need to get the prom reprogrammed for these changes. This will insure that it runs properly.

Fuel lines modifications

Adapting a OEM twin blade TB

Fuel lines modifications

You should have a minimum 3/8 feed line and 5/16 return line. If the return line is restricted, it will cause a high pressure situation. We do not have a generic kit that will supply everything for your installation. There are too many variables in each project to create such a kit. Also, we cannot carry the liability on the fittings and such required to do so. Please take your time during this modification and use all fuel injected rated items and check for leaks BEFORE you build the entire FIRST unit. Please contact us with any questions, we are always glad to help!

Throttle connections

Throttle connections

Throttle connections

This is an area that many do struggle with. There are many configurations out there for throttle cable connections. This makes it extremely difficult for us to make a universal one fits all throttle body. We do offer a long throttle pin for an OEM tpi cruise/ throttle connection . The cable ends do sometimes need to be cut to fit and the corresponding connection added to your cable needs to be installed. We can help you with this if you contact us with your needs. Generally speaking worse case scenario is a lokar cut to fit cable can be used on pretty much any application.

Download FIRST Tpi Installation Manual/ Fast manuals here

PLEASE NOTE: The Fast EZ manuals have a picture of a throttle body type efi, but the intructions are the same for the FIRST TPI.

Video

Check out this great video featuring the removal of a carb set up from a 1977 Chevy Monza to the FIRST tpi with the fast 2.0.

Video

Check out this great video featuring a 1989 Trans am GM tpi removal and the install of the FIRST tpi using all the oem obd1 electronics and sensors.

Helpful Tech tips and information

Early style throttle body mounting

Early style throttle body mounting

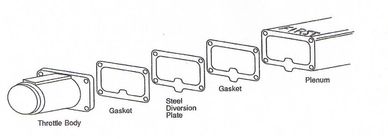

The early style plenum required a steel diversion plate to seal off the EGR port properly. It was common for these to be removed because customers did not understand why it was there. If this plate is missing, just give us a call we have them for sale.

Steel diversion plate

Early style throttle body mounting

This plate is needed to properly seal the EGR port so there is not a large vac. leak under the throttle body flange.

Diversion plate not installed

Diversion plate not installed

Notice the large hole that is left open under the throttle body flange when the plate is not installed. This plate is used to apply pressure for the gasket to seal.

Diversion plate installed

Diversion plate not installed

Now you can see how the hole is sealed off when the plate is properly installed, no more vac. leak!

Large cap HEI modification

You can use the GM large cap distributor with the FIRST® TPI, however because of the large size of the base runner you will more than likely need to remove some of the lower casting on the dist. base to allow room for adjustment.

Fuel rail layout

The FIRST® fuel rails are 6016 billet aluminum with 3/8 NPT female on each end. You can use many different combinations to make your connections. You can use hose barbs with fuel injection rated line. You can use an 3/8 NPT male to 3/8 NPT female inverted flare to use steel lines or even flare your existing steel lines. You can also adapt AN fittings to the rails. Typically we use the crossover in front for clearance reasons and use the rear exits for the main feed line and out to the fuel regulator. It is possible to use a long loop of fuel line to go around the dist. if you need to use the front for feed and return.

Fuel pump and filter layout

It is a good idea to have a pre fuel pump filter to catch debris from the tank, then the fuel pump and then another filter after the pump which will catch debris from a failing fuel pump before it gets to the fuel injectors!

Cold air intake

It is usually fairly simple and recommended to add a cold air intake set up in most applications. This really does help keep cool air going into the intake. Room can sometimes be an issue we know this, but we have always been able to figure out a way to get it done. 4" couplers and 4" aluminum tube in this picture with the K&N filter behind the grille.

Proper return spring installation

Proper return spring installation

The return spring tab should be mounted like in the picture, so that when full throttle is achieved the spring will run along side of the lever like in the picture. You should not need to move the location of the spring tab to achieve proper return pressure. If you feel it is not providing the proper return to idle pressure more than likely something else is wrong and you should contact us so we can help you figure out your situation. We do not charge to inspect throttle bodies, no matter what the age. Just cover shipping charges.

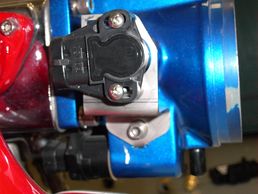

Proper TPS mounting

Proper MAP bracket install

Proper return spring installation

There should be no pressure on the TPS bracket at all, the job of the bracket is to hold the TPS so that the TPS lever on the throttle shaft can properly contact the TPS lever during rotation of the throttle shaft. If for some reason you feel something is not correct, please contact us so that we can walk you through this situation. The part number for the "standard" brand is TH37T.

Proper TPS mounting

Proper MAP bracket install

Proper MAP bracket install

It is OK if the TPS touches the throttle shaft screw as they should move in time together like the late model TPS that mounts directly to the shaft. If you feel that something is not correct please contact us so that we can walk you through this situation.

Proper MAP bracket install

Proper MAP bracket install

Proper MAP bracket install

This is how the MAP bracket is properly mounted. Yes, you do need to hook up the vac. line to one of the 1/4 vac. fitting on the plenum!

Manifold absolute pressure (MAP) sensor

Intake air temp (IAT) or manifold air temp (MAT) sensor

Manifold absolute pressure (MAP) sensor

Part number for "standard" brand is AS5T.

Intake air temp (IAT) sensor location

Intake air temp (IAT) or manifold air temp (MAT) sensor

Manifold absolute pressure (MAP) sensor

This is where the IAT sensor is typically mounted on the FIRST TPI. It can be mounted anywhere in the plenum area or intake tubing.

Intake air temp (IAT) or manifold air temp (MAT) sensor

Intake air temp (IAT) or manifold air temp (MAT) sensor

Intake air temp (IAT) or manifold air temp (MAT) sensor

Part number for "standard" brand is AX1T

Idle air control (IAC) mounting location

Intake air temp (IAT) or manifold air temp (MAT) sensor

This is where the IAC valve is mounted on the FIRST TPI Throttle body.

Idle air control (IAC) valve

Part number for "standard" brand is AC1T

Oxygen sensor (O2)

Coolant temp sensor

Coolant temp sensor location

Coolant temp sensor location

The part number for "standard" brand is TX3T

Coolant temp sensor location

Coolant temp sensor location

Coolant temp sensor location

This is a typical coolant sensor location on the FIRST TPI. It can be mounted anywhere in the coolant passage.

Important bolt to seal

Coolant temp sensor location

Installed Throttle cable bracket

It is necessary to use sealant on the passenger front lower runner bolt, this does go into the front coolant passage.

Installed Throttle cable bracket

Installed Throttle cable bracket

This is the proper way to mount the throttle cable/ Detent bracket. We have seen installs where this bracket is mounted upside down or on the forward bolts and this is totally incorrect. This bracket has been designed to be mounted like in the picture. The angles are correct for the throttle cable, cruise cable and detent cable including the 700r4 trans which we run in many vehicles with the FIRST® TPI. If for some reason you cannot seem to get your cables to function with this bracket set up this way, please contact us so that we can work through this situation with you.

Good tool to have

Your install of the runners will go much easier, if you have an extended 3/16" ball end hex socket. This will allow easier positions to get the hard to reach under the plenum and lower runner bolts.

Possible coil mounting location

You can use the machined boss on the right rear section of the base manifold to mount a small cap distributor remote ignition coil when not using the vortec heads.

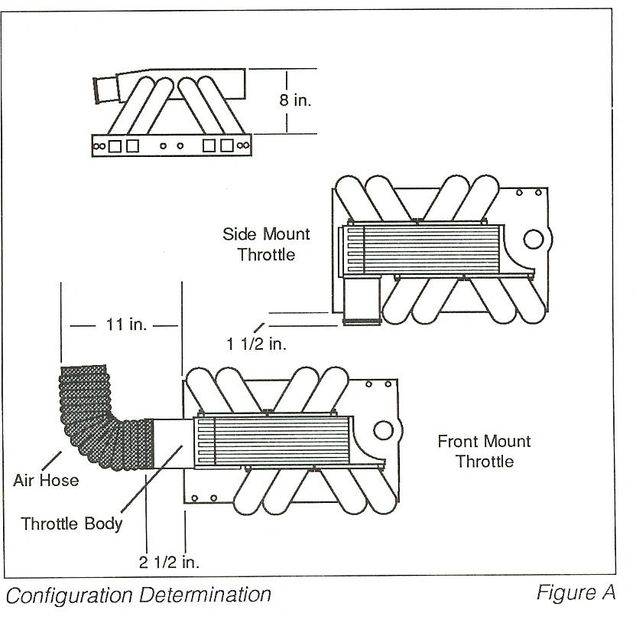

FIRST TPI Dimensions

DIMENSIONS

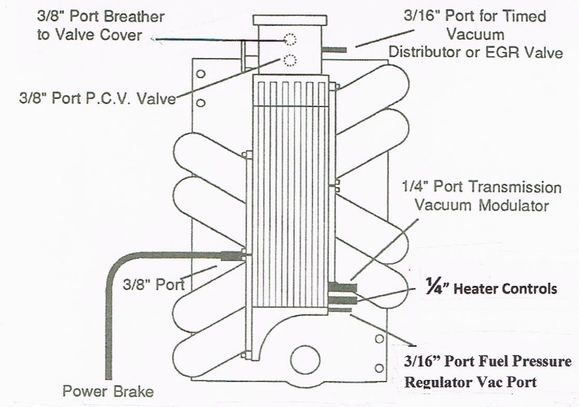

Vacuum Ports

dyno examples

This is 1 older magazine test, more to come as we find others we have.

Copyright ©2000- 2025

First Performance Center, LLC - All Rights Reserved.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.